Restaurant maintenance and repairs are typical in the industry due to the heavy usage of tools and equipment in the kitchen. This is an area of food-related businesses that’s easily mismanaged. In this article, we’ll cover the following topics:

- The importance of managing repairs and maintenance in a restaurant

- Detailed steps on how to handle this area of your restaurant

- How to improve staff training and optimize workflow to reduce repair and maintenance incidence

You’d be surprised at the number of restaurant owners and managers who don’t pay as much attention to detail as they should in this area. When you finish reading this article, you’ll be prepared to create a full current assessment of your equipment, create a budget and schedule for maintenance and repairs, and implement a list of best practices your staff can follow to keep equipment in top shape. Let’s dig in!

The Importance of Managing Repairs and Maintenance in a Restaurant

Managing repairs is obvious for numerous reasons—your restaurant won’t work if the most crucial tools and equipment needed for service are damaged. However, maintenance is usually neglected or only done when it’s required by laws and regulations. If that’s the case for your restaurant, you must know your business is endangered! Maintenance is a preventive measure that increases your control over tools and equipment and their overall usability. You can save money by using proper cleaning and maintenance tools and training. That also gives you the advantage of knowing the current state of your equipment, which prepares you to buy new equipment without hindering the business. Finally, repair and maintenance practices are crucial for restaurant efficiency, safety, and customer satisfaction—tools are necessary for all production, after all.

Advantages of Maintaining and Repairing Your Equipment

Here are some of the advantages of managing repairs and maintenance:

- Reduced downtime and minimized equipment failures. If you know a piece of equipment needs maintenance, you can do it before it’s too late. Also, if you do it once, you’ll be prepared to do it even faster.

- Enhanced safety for employees and customers. Most of the equipment inside a restaurant’s kitchen can be dangerous to the staff using it. Also, some equipment, like cutting boards, should be replaced often to avoid cross-contamination and other dangers that affect customers.

- Extended equipment lifespan and reduced replacement costs. In the case of several tools, it’s much cheaper to replace them instead of fixing them. However, with proper maintenance, you won’t get to the point of having to replace them in the first place. Additionally, maintenance is much cheaper than replacing them altogether.

- Improved operational efficiency and productivity

- Enhanced customer satisfaction and positive dining experiences

Disadvantages of Not Maintaining and Repairing Your Equipment

And these are the disadvantages of neglecting your equipment:

- Increased risk of equipment breakdowns and costly repairs. If you do not upkeep your equipment, it’s more likely to fail, cause accidents, and more.

- Potential health code violations and fines. Keeping your restaurant up-to-date with local regulations and codes is vital to operating. Not meeting the requirements can have your restaurant fined or, in the most extreme cases, closed.

- Safety hazards for employees and customers. Aside from costly repairs, broken equipment can cause other issues, like damage to other equipment or inventory losses, which can cause food poisoning.

- Damage to brand reputation and customer loyalty.

- Increased labor costs due to unplanned downtime. Even when restaurants are not making money, they’re costing money by adding up on bills!

To summarize, if you’re not maintaining your restaurant’s equipment outside of what is required by law, you’re endangering your business immensely.

How to Manage Maintenance and Repairs for Your Restaurant

Now, let’s get started with the best part of this guide—the how. In this section, we’ll cover every step you must follow to get started from zero with maintenance and repairs for your restaurant. This is perfect for new restaurant owners who haven’t implemented these practices, as well as for those who have been running a restaurant for a while without them. Keep in mind that, in some cases, it can be too late to start applying this maintenance strategy, but it’s very likely the restaurant will let you know of this in advance—by failing and closing, that is. If you’re here, it’s not too late!

1. Assess Your Current Situation in the Area of Restaurant Maintenance

Here's a step-by-step guide to assessing the current state of your restaurant's equipment:

1.1 Gather Information

The first step is to learn about the equipment you currently use. Gathering information about equipment outside of the kitchen (for example, bars and outdoor grills) and other equipment not directly related to service (air conditioners in office spaces) is also a good practice. Here are a few tips that can help you gather information and organize it:

- Make a list: Start by creating an exhaustive list of all your restaurant’s kitchen equipment, including major appliances (ovens, refrigerators, and dishwashers), smaller appliances (blenders, coffee makers, and toasters), and any specialized equipment (food processors, slicers, and meat grinders).

- Review manuals: Find the user manuals for each piece of equipment. These will contain important information about maintenance schedules, troubleshooting tips, and safety precautions.

- Check warranty status: Note down the warranty status of each item. This will help you determine if repairs are covered or need to be budgeted for.

This information will come in handy when starting a repair and maintenance schedule and budget later on. You can also pair all the information with useful manufacturer and review websites, which can help you scout for replacement parts and even technicians.

1.2 Conduct a Visual Inspection

A visual inspection is vital to finding out more about the current state of the equipment. We highly recommend that you take as many notes as possible and organize them together with the aspects mentioned above. Here are a few tips on what to look out for during your inspection:

- Look for wear and tear: Pay attention to any visible signs of damage, such as dents, cracks, rust, or loose parts. Check for worn-out seals, frayed cords, and broken buttons or knobs.

- Cleanliness: Assess the overall cleanliness of the equipment. Look for food residue, grease buildup, and limescale deposits, especially in hard-to-reach areas. This can help you understand the usage and how to organize cleaning and maintenance schedules efficiently for that specific piece of equipment.

- Leakages: Check for any leaks, drips, or condensation around faucets, hoses, and connections. This is useful for learning about the weak points each piece of equipment might have, as they are the areas that will cause the most repairs and issues.

Take this opportunity to familiarize yourself with the equipment. You can maximize your learning about specific pieces of equipment by reading up on the manual as you inspect it visually. However, do not make the mistake of assuming you should start cleaning right away. Untrained hands can be more harmful than helpful, especially when it comes to delicate kitchen equipment.

1.3 Test Functionality

You can take care of this step along with the visual inspection. Here’s what you should do and keep an eye out for:

- Power up: Turn on each piece of equipment and test its basic functions. Listen for unusual noises, vibrations, or temperature changes.

- Temperature control: For ovens, refrigerators, and freezers, check if they are maintaining the correct temperatures. Use an independent thermometer to verify.

- Water pressure: For dishwashers and other water-using equipment, check the water pressure and flow. Also, check other related equipment, such as grease traps.

Another good practice to keep in mind in this and the previous steps is asking your staff about their experience using the equipment and tools. That can give you excellent insight into how they work daily, when and if they start to fail, and if they are a bottleneck for production, among other things.

1.4 Pay Special Attention to These Things

Here are some things you might overlook during this process:

- Safety features: Ensure all safety features are functioning properly, such as door locks, pressure relief valves, and automatic shut-off mechanisms. This can help you catch issues like faulty safety systems, which can be catastrophic to your restaurant if they’re not working properly.

- Hygiene: For equipment that comes into contact with food, pay close attention to cleanliness and sanitation. Check for cracks or crevices that could harbor bacteria. It will also be very useful to review the cleanliness of your staff and how they maintain their working surfaces and areas.

- Energy efficiency: Look for signs of energy waste, such as excessive heat radiating from appliances or long cooling times. Consider upgrading to energy-efficient models if necessary. This can take hundreds of dollars off your electricity bill.

As you assess each piece of equipment, note down your observations and any potential issues. This will help you prioritize repairs and schedule maintenance tasks. For any visible damage or malfunctioning parts, take pictures as documentation. This will be helpful when contacting manufacturers or repair technicians.

2. Steps to Create a Maintenance Schedule

Now that you have all the necessary information, it’s time to create a maintenance schedule. Maintenance schedules are very useful—you can’t simply keep all of those details in mind, especially since not all of the equipment needs maintenance at the same time. Limiting maintenance efforts to times when they’re strictly necessary is also a good practice to get all the benefits without lowering your restaurant’s profits too much. Now, let’s take a look at how to create a schedule.

1. Identify Maintenance Requirements for Each Piece of Equipment

The first step is pretty much the same as the previous steps—you must understand each piece of equipment and its needs. Here are a few examples:

- Gas ovens: Check for leaks in gas lines and connections; clean burner ports and drip pans; replace worn-out igniters and thermostats.

- Refrigerators: Regularly defrost and clean coils and condenser units to ensure efficient cooling. Replace worn or damaged door seals to prevent cold air from escaping and food spoilage and ensure they maintain proper temperatures

- Dishwashers: Regularly clean and replace dishwasher filters and spray arms to prevent clogging and ensure proper cleaning. Ensure the dishwasher has adequate water pressure and check the detergent and rinse dispenser levels. Use a sanitizing solution to disinfect the dishwasher interior and prevent the growth of bacteria.

Do this for all of the equipment you want to consider.

2. Develop a Detailed Maintenance Schedule

Now it’s time to develop the maintenance schedule. All of the necessary maintenance and cleaning procedures must be done periodically and with varying regularity. For example, you can clean gas ovens and repair minor issues every month, but you should deep clean dishwashers at least two to three times per week. This means you’ll be able to schedule the maintenance of the equipment for days, weeks, or months apart, which will make it much more manageable.

Here are other considerations to keep in mind when creating the schedule:

- Frequency of the cleaning and maintenance

- Weekly: Clean ovens and grills, replace fryer oil and filters, sanitize dishwashers, and check and clean refrigeration unit condenser coils.

- Monthly: Clean and disinfect ice machines; check and replace gaskets and seals on equipment; test and calibrate thermometers for accuracy; sharpen blender and food processor blades.

- Quarterly: Schedule professional maintenance for ovens, refrigerators, dishwashers, and other complex equipment. Deep clean and sanitize ventilation systems and exhaust hoods.

- Annually: Inspect all equipment for major wear and tear and update or replace outdated or inefficient models if necessary.

- Prioritization

- Critical equipment: Prioritize equipment essential to daily operations, like refrigerators, ovens, and dishwashers.

- Safety hazards: Address any issues that pose safety risks, like gas leaks, faulty wiring, or malfunctioning safety features, immediately.

- Efficiency: Schedule maintenance for equipment affecting energy consumption, like cleaning condenser coils or replacing worn-out filters, to optimize efficiency.

- Staff workload: Spread out maintenance tasks to avoid overloading your staff on specific days.

- Documentation and tracking

- Create a master schedule: Develop a visual chart or spreadsheet outlining all equipment, their maintenance needs, and their frequency.

- Assign tasks and responsibilities: Designate who is responsible for each maintenance task.

- Track completion: Keep records of completed maintenance tasks for future reference and warranty purposes.

- Review and adapt: Regularly assess your schedule's effectiveness and adjust it as needed based on equipment performance, usage patterns, and budget constraints.

All of these details will allow you to create a highly organized and effective cleaning and maintenance schedule.

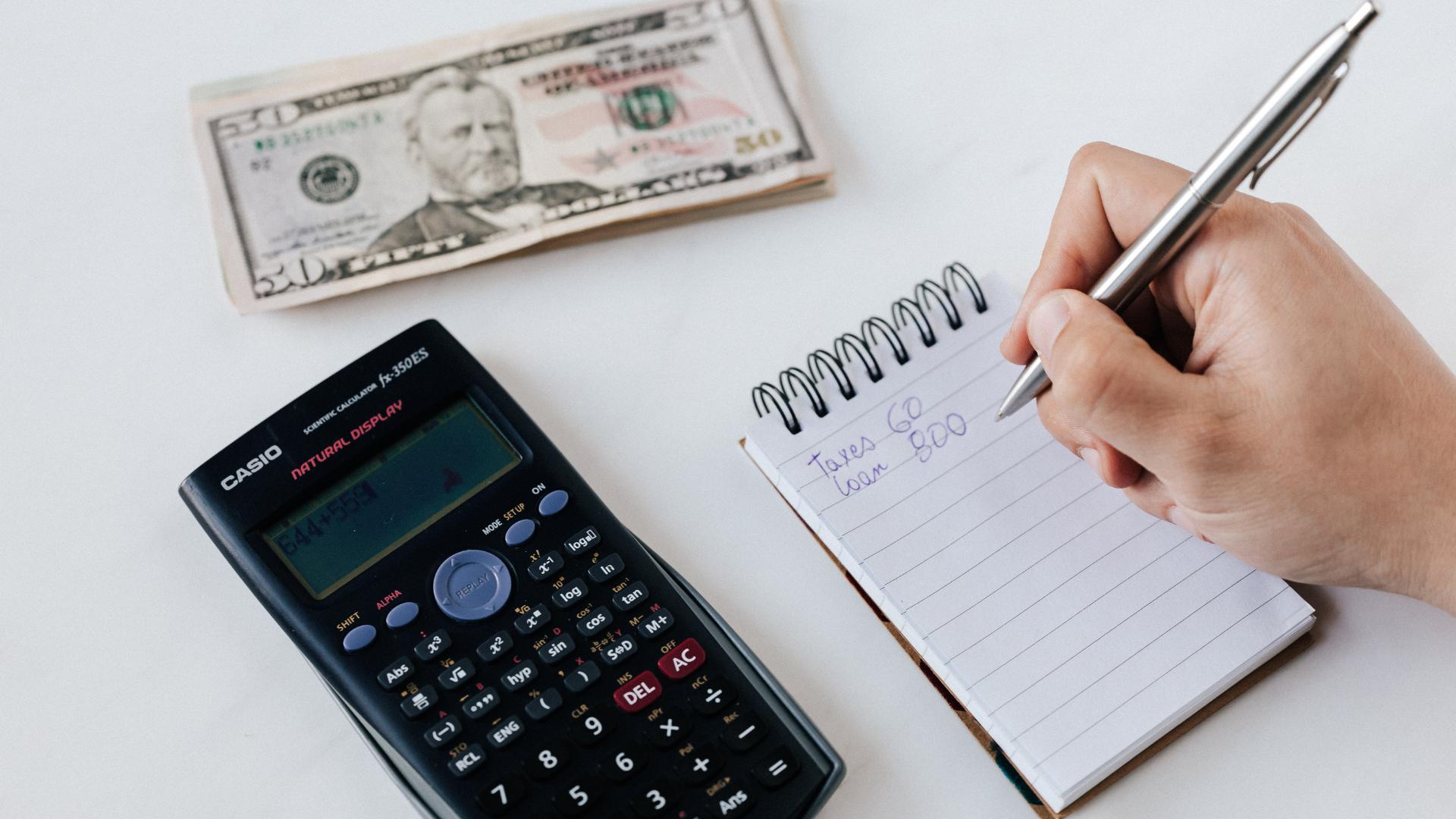

3. Creating and Managing a Repair, Replacement, and Maintenance Budget

Working with as many details as you can will give you numerous advantages. One of the details you must consider is the budget. The budget, most of the time, will be the limiting factor in applying all of the maintenance, repairs, and replacements. This is especially true if you must take care of these issues as fast as possible—time is money, after all. So, to help you avoid overspending on issues that could have been avoided, you now have the previous schedule. But the second part is having a budget allocated to these expenses when the time comes. A good rule of thumb is to allocate 10% of the restaurant’s monthly net profits to the maintenance and repair budget. The amount will vary depending on the restaurant’s profits, which will probably be adequate for equipment maintenance, repair, and replacement expenses. Additionally, it’s a good idea not to cap the amount the budget can build up to and never take money out of it unless it’s strictly necessary. However, those are very lax measures, which might not adapt properly to your restaurant. Below are the steps you can follow to create and manage a budget for this area of your business efficiently.

1. Gather Historical Purchase, Repair, and Maintenance Cost Data:

This aspect is simply and only applicable to restaurants that have been operating for a while. Keeping tabs on how much you spend when repairing and maintaining your equipment (and everything it requires, such as cleaning solutions and tools) is a great practice you should apply. Get used to it, as it will allow you to easily compare prices and look for cost-cutting opportunities.

If your restaurant is new, you can also use purchase data as a starting point and gather the rest of the information about repair, replacement, and maintenance costs by asking around for prices. Doing this even though you won’t need it if the equipment is new gives you a useful frame of reference to compare future expenses.

2. Develop a Comprehensive Budget

After gathering all the information, you can create a budget for future equipment repairs, maintenance costs, and replacements. Here are a few tips that can help you in this process:

- Create a consistent budget for maintenance expenses. This includes buying cleaning solutions, gloves, and masks, among other things. This will be the most affordable part of your budget, but it can save you a lot of money in the long run.

- Create a budget for repairs and quick replacements. You can gather a bit more information about specific equipment to help you with this step. For example:

- You can ask a technician about the most frequently replaced parts of a specific piece of equipment.

- Add up the cost of each and calculate the average cost of the replacement to use as a failsafe budget.

- Create a budget for full replacements.

- The best you can do about this is to calculate the average cost of the equipment in your restaurant.

- Double the average cost and keep that as a reserve for emergency replacements.

- Doing this on top of having insurance is a great practice. It’ll allow you to act as fast as possible before the insurance is approved (which usually takes time), so your restaurant keeps operating through the crisis.

Finally, it’s a good idea to review and adjust the budget based on equipment, operations, or maintenance requirements and changes.

Training Staff to Reduce Maintenance Costs

Restaurants are versatile businesses in that, depending on your staff participation, job description, and training, they can help you save a lot of money—while applying reasonable practices, of course. You can achieve this in your business by providing your staff with the proper tools and training to take care of the most common maintenance tasks. Here are a few examples of said tasks:

- Scrubbing and degreasing ovens and grills

- Cleaning and disinfecting dishwashers, including filters and racks

- Wiping down refrigerators and freezers, including door seals and shelves

- Sharpening blender and food processor blades using appropriate tools

- Sharpening knives with a whetstone or honing rod

- Changing water filters in refrigerators and ice machines

- Applying food-grade lubricant to moving parts on equipment like slicers and mixers

- Greasing hinges and rollers on doors and drawers

- Sanitizing walk-in coolers and freezers

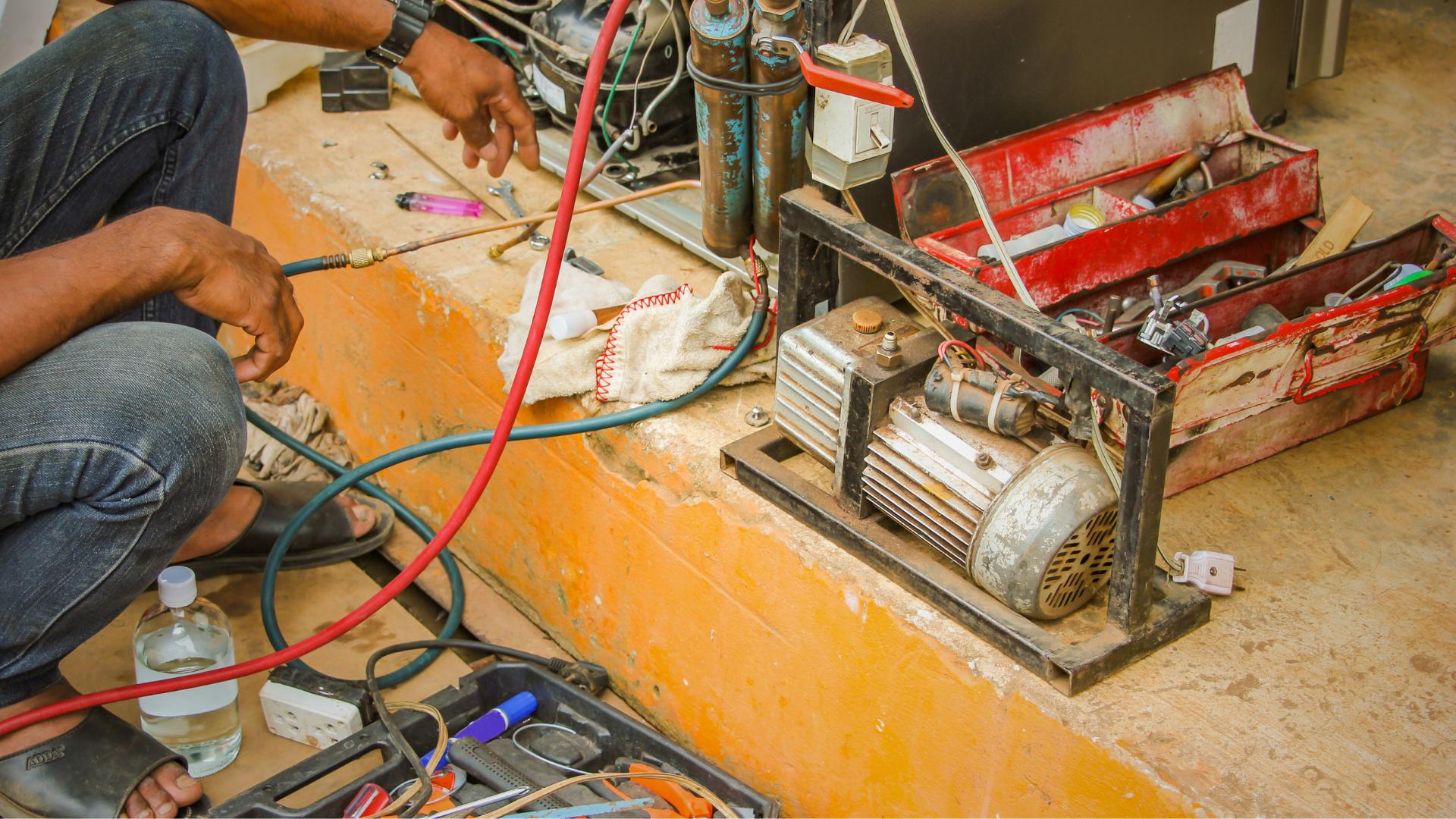

Of course, they shouldn't take care of more complex tasks, such as repairing a damaged oven or even replacing parts of equipment, regardless of how simple it looks on a YouTube video. You should always have a few knowledgeable technicians on speed dial for the most complex machines, such as refrigerators, stovetops, kitchens, ovens, and more. With that in mind, below are a few steps you can follow to optimize the maintenance of your restaurant.

1. Educate Staff on Proper Equipment Operation and Maintenance Procedures

This is something you should include in the job description, so you can start by adding that to them if you haven’t already. Additionally, you should create procedures for each of the equipment pieces in your restaurant and add them to your restaurant’s operations manual. By doing so, it’s recommended that you provide training on daily cleaning, inspection, and troubleshooting tasks and also emphasize the importance of reporting equipment issues as they arise. Check out our guide on restaurant staff management to learn more about how to create training processes.

Here are other good practices you can apply at the same time:

- Establish protocols for proper equipment usage, cleaning, and storage

- Encourage employees to handle equipment with care to prevent damage or premature wear

- Integrate maintenance tasks into routine operational checklists

- Recognize and reward employees for proactive maintenance efforts

With the right cleaning and maintenance practices, your staff can help you extend the life of your equipment.

2. Monitor Equipment Performance and Usage Patterns

Finally, you must consider that restaurants aren’t consistent businesses. Some months you can have hundreds of clients, and others you can only get a fraction of that. You must also consider that when determining maintenance practices. Cleaning and maintaining tools as needed is a good alternative for long periods without clients, but also for periods of high productivity to maintain the quality of the food and processes. To adapt easily to these changes, use the following tips:

- Standardize cleaning and maintenance. The quicker you can do it while maintaining efficiency, the better.

- Track equipment usage to identify potential issues and optimize maintenance scheduling

- Analyze trends in equipment performance to identify potential problems early on

- Create an efficient communication system with your staff. If something goes wrong, you shouldn’t be the last to find out!

Adapting to these changes comes with adapting to the nature of the restaurant business.

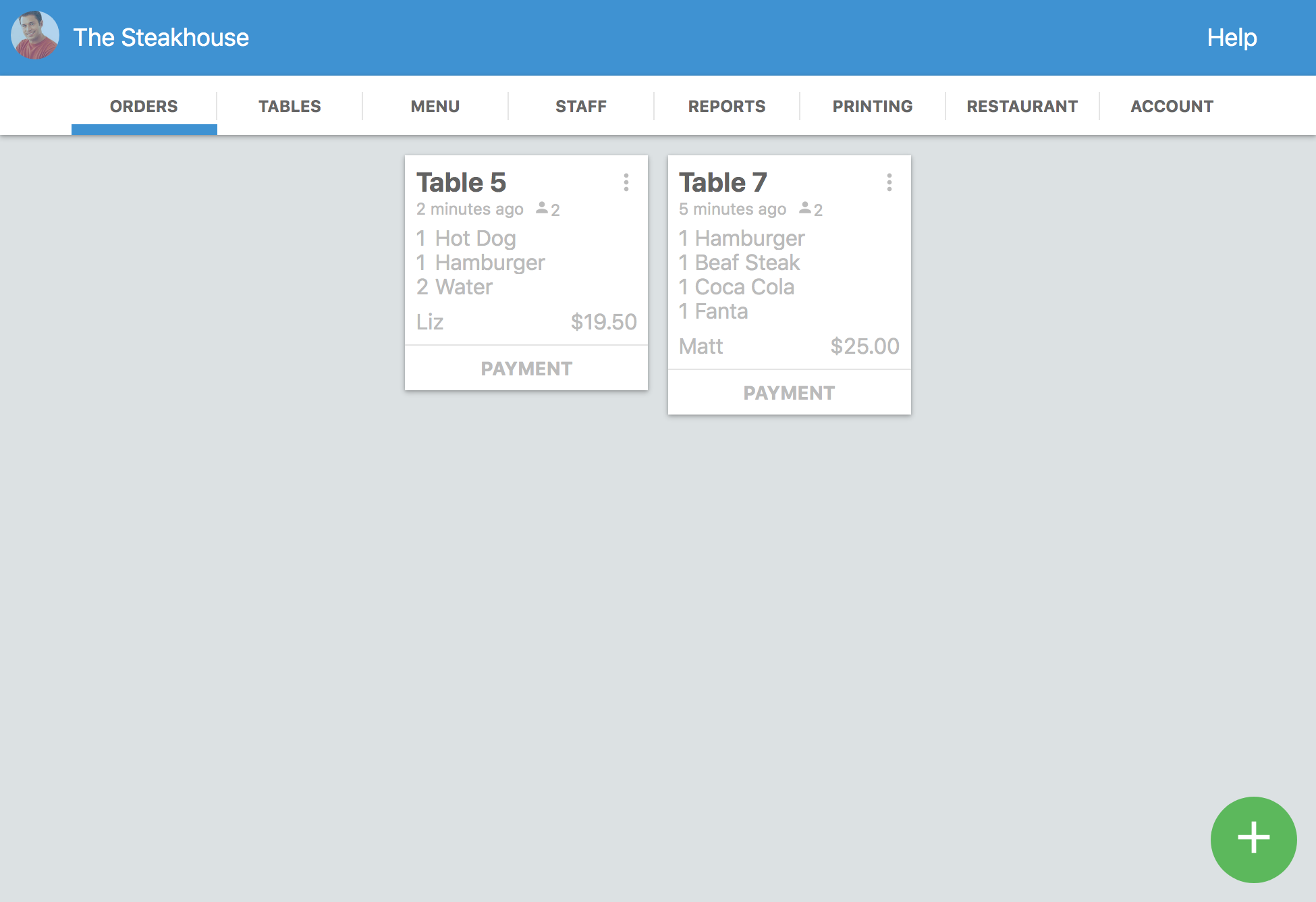

Owners and Managers Can Become Experts at Foreseeing Maintenance Issues

If you’re a new restaurant owner, this management-level foresight will come to you eventually. Still, you’re not completely unarmed; you just need to gather the proper tools in the meantime to help you manage this area of your business. A quick and safe way to measure your restaurant’s productivity is by looking at sales. A reliable restaurant POS system like Waiterio can give you all the necessary information you need to adapt to these changes before they happen. Learn more about Waiterio here. Are you taking proper care of your restaurant’s equipment? You should!